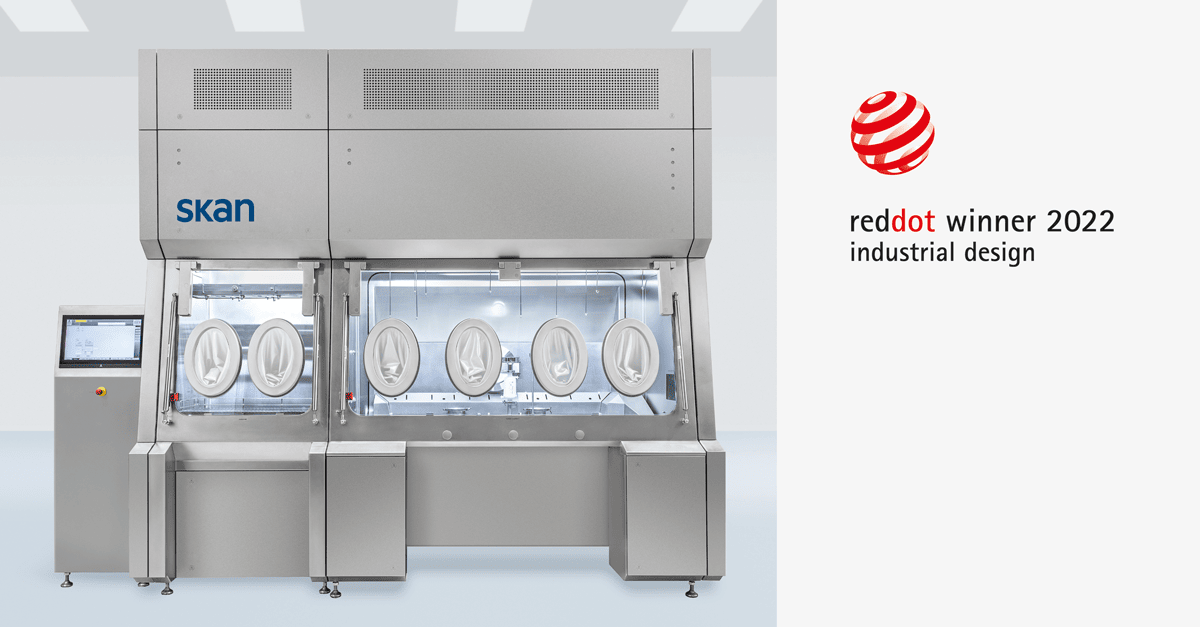

The new version of the VarioSys® isolator (PSI-L 2.0) impresses with new functionality and clear design. The VarioSys® integrates highly efficient filter cartridges (FiPa), high-performance catalysts and the patented skanfog® flow system. This not only ensures reliable cycles with lower H2O2 consumption and significantly reduced cycle time, but also the highest possible process reliability. At the same time, the VarioSys® isolator system is more flexible than ever and can be optimally adapted to all products and processes. In addition, the unique L-flange enables even more efficient replacement.

The VarioSys Isolator system offers an unprecedented modularity and flexibility, which makes it possible to meet the requirements of the most diverse manufacturing processes.

The unique features of the VarioSys® isolator system

- Complete killing of a 106 population of Geobacillus Stearothermophilus is validatable and reproducible

- Aseptic and toxic production by H2O2 decontamination of the isolator

- Isolator with quick and easy exchangeable modules

- Empty flange plate guarantees more flexibility

- Robot safety to minimize risk for operator and process

- Operator protection through safely replaceable FiPa filters

- Suitable for many types and sizes of ready-to-use packaging materials

For more information please visit variosys.com/en.

Get in touch with our sales team!

The SKAN PSI-L 2.0 isolator has received the Red Dot Award 2022: Industrial Design. The “Red Dot” award stands for high design quality.