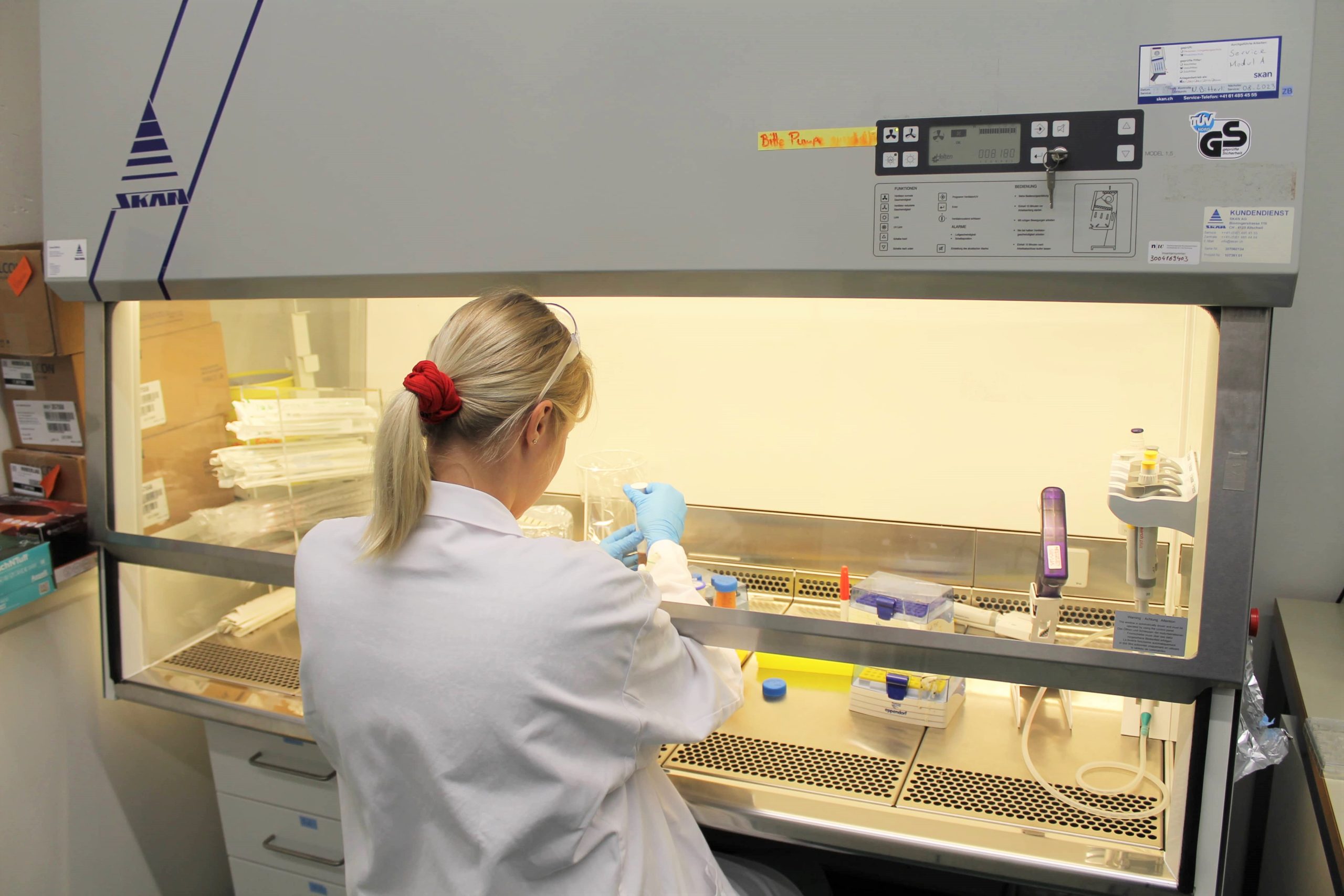

Understanding the user’s processes is one of our strengths. Our know-how is unique because we not only benefit from our own decades of experience, but also from the expertise of our customers.

For customers

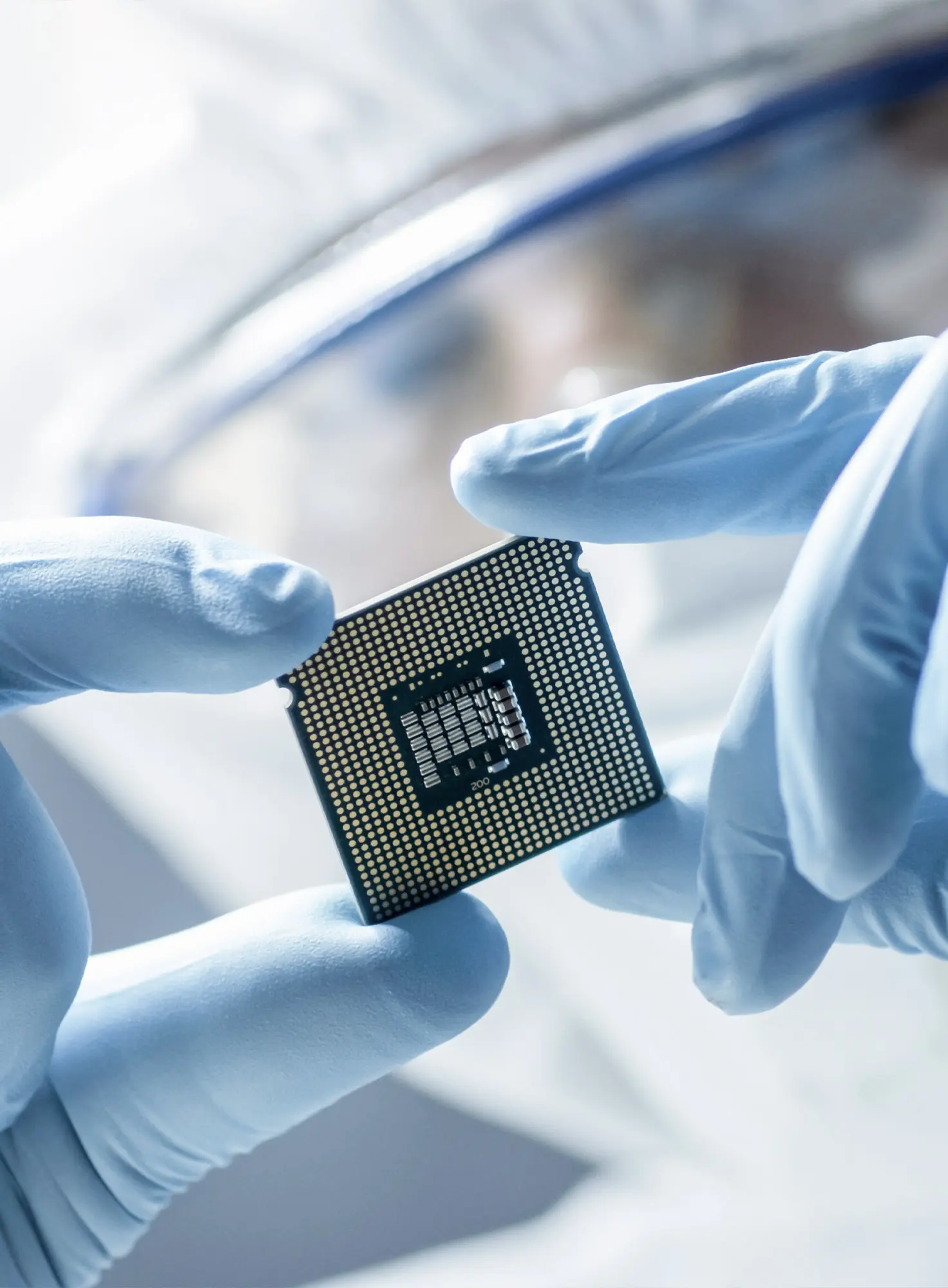

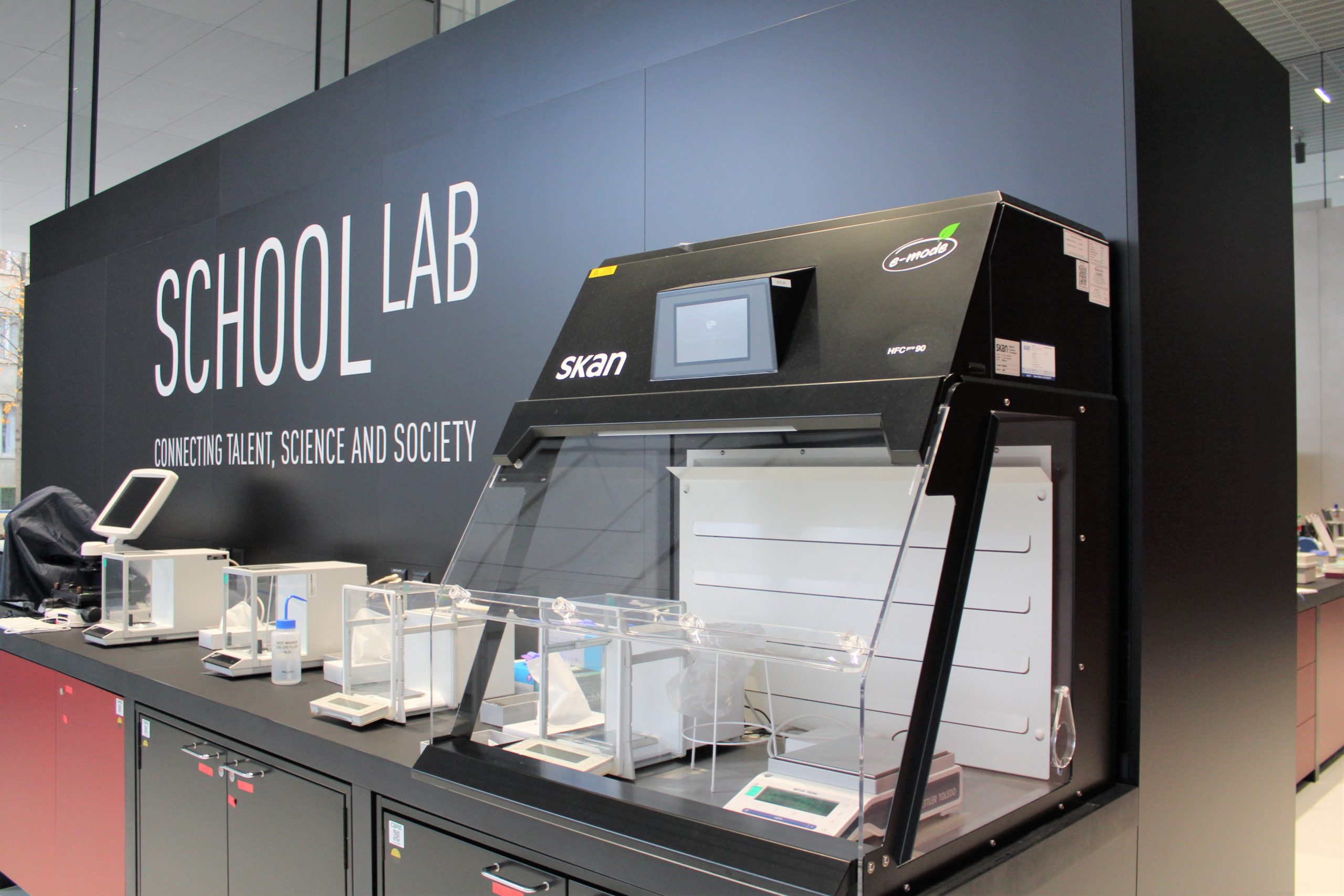

The business unit Pure Solutions offers worksite solutions in the field of pure air. Whether it is a matter of decontamination, filtration or protected areas: We have the optimal solution to ensure the product, user and environmental protection of our customers.

This enables us to ensure that our customers receive the added value from our products and services that they expect today and in the future.